Preparation of Recycled Carbon fiber/Polypropylene Fiber Felt and Research on Properties of its Compression Molded Composites

Recycled carbon fiber (RCF) and polypropylene (PP) fibers were used as raw materials. RCF/PP fiber felt was prepared by nonwoven process, and then RCF/PP composite material was prepared by hot pressing. The nonwoven process parameters and molding parameters were explored, and the material properties were studied.

The results show that the needle punching process uses a needle punching density of 15pin/cm2 and a needle punching depth of 10mm; the thermal bonding process uses a pressure of 130-180N/cm2 and a temperature of 160-180℃. The composite material consolidated by needle punching was hot pressed at 190℃ and 6MPa; the composite material consolidated by thermal bonding was hot pressed at 177-180℃ and 7MPa.

The tensile properties of the needle punched felt in the CD direction are 77.8% higher than those in the PD direction, and the tensile properties of the thermal bonding felt in the CD direction are 59.3% higher than those in the PD direction. The RCF/PP composite material has a certain degree of anisotropy.

Carbon fiber reinforced plastic (CFRP) has an obvious advantage of high specific strength compared to metal materials, so it has developed rapidly in recent years. However, how to deal with CFRP that has reached its service life or is damaged and scrapped has become a major problem. Especially in the context of “carbon neutrality”, the recycling and reuse of CFRP is even more important.

At present, the methods for recycling carbon fiber in CFRP can be divided into chemical recycling, physical recycling and energy recycling. At present, chemical recycling is the main way to recycle CFRP. Chemical recycling is to use chemical modification or decomposition to make CFRP waste into other recyclable substances. Chemical recycling methods can obtain clean recycled carbon fiber, which mainly includes pyrolysis (high temperature pyrolysis), fluidized bed recycling and supercritical fluid method.

Among them, pyrolysis is also the main CFRP recycling method that has achieved commercial operation. Compared with the original carbon fiber, the strength, modulus and fiber length of the recycled carbon fiber (RCF) obtained after recycling will decrease to varying degrees.

In this case, RCF is difficult to make into traditional prepreg. Using nonwoven technology to make RCF and resin fibers into felt can maximize their performance. Nonwoven technology is a special textile technology that orients or randomly arranges short fibers or filaments to form a fiber mesh structure, and then uses mechanical, thermal bonding or chemical methods to reinforce it.

Its products have the characteristics of softness, breathability, and three-dimensional structure. The use of this technology to prepare CF/PP fiber felt can evenly mix CF and PP, improve the impregnation of thermoplastic resin into CF, and thus improve the interface performance between thermoplastic resin and CF. It is worth mentioning that mixing carbon fiber and polypropylene fiber before impregnation can effectively shorten the impregnation process, and combined with the simple compression molding technology of equipment operation, it can become a rapid molding method for composite materials.

Manis et al. used RCF and thermoplastic fibers to make felt and evaluated the effects of thermoplastic fibers on processing, fiber shortening and mechanical properties. The results show that within a certain range, the increase in the content of thermoplastic fibers can reduce the damage of RCF and reduce its length loss, thereby improving the mechanical properties of the composite material.

This paper studies the preparation process parameters of RCF/PP felt and the mechanical properties of its compression-molded composites through experimental methods. A set of practical preparation process parameters of RCF/PP felt is summarized, and a deeper understanding of the mechanical properties of RCF/PP felt compression-molded composites is obtained.

1 Experimental Materials and Sample Preparation Methods

1.1 Preparation of RCF/PP Fiber Felt

RCF/PP fiber felt is a blend of RCF and PP fibers. The RCF used was provided by Shanghai Lingang Zhishi Company, which is a carbon fiber recycled by pyrolysis, as shown in Figure 1; the PP fiber used was provided by Daiwabo Polytec, Japan.

The preparation process is to first pre-open the RCF and PP fibers respectively, and then mix the pre-opened RCF and PP fibers in a weight ratio of 40:60 and perform secondary opening, combing, cross-laying and consolidation in sequence, and finally obtain RCF/PP fiber mixed felt.

The specific non-woven fiber felt preparation process is shown in Figure 2. The equipment used in the non-woven preparation process of this experiment is provided by Changshu Weicheng Nonwoven Equipment Company, as shown in Figure 3.

1.1.1 Carding to Form a Web

After pre-opening and mixing, RCF and PP fibers are transported to the carding equipment, as shown in Figure 4. The carding machine includes a pre-carding and opening system, a main carding system, and a condensing and outputting system.

The pre-combing and opening system consists of a licker-in roller covered with card clothing, a chest cylinder and working and stripping rollers (1-4 groups) on it. In this system, RCF and PP fiber bundles are initially decomposed and mixed.

After the fiber is fed, it is transferred to the chest cylinder through the licker-in roller. The fiber is simply combed in the working area between the chest cylinder and the working roller. The combing process at this time is generally called free combing. Free combing is the interaction between the chest cylinder and the working roller. The needle teeth of the working roller control the fiber, and the needle teeth of the chest cylinder comb the fiber at the same time. The combing effect is affected by the rotation speed of the two. The linear speed of the chest cylinder is required to be much higher than the linear speed of the working roller during the combing action.

When the fiber just enters the carding machine, it has the characteristics of thick fiber layer and large fiber bundle. At this time, the fiber state is disordered, so a certain combing force is required to ensure the combing effect. When selecting the card clothing, it is necessary to consider RCF, a special raw material, and fully consider the strength of the card clothing.

The main combing system consists of a main cylinder covered with card clothing and working and stripping rollers (4-6 groups) on it. In this system, the fiber bundles are gradually decomposed into single fibers, combed and oriented, and evenly mixed.

The main combing flow chart is shown in Figure 5. Similarly, in order to play a combing role, the linear speed of the cylinder needle surface is much higher than the linear speed of the working roller needle surface, and most of the fibers enter the next working roller combing area under the traction of the cylinder. While combing the fibers, a part of the fibers are captured by the stripping roller. There is also a stripping action between the stripping roller and the working roller, and between the stripping roller and the main cylinder: the fibers after the combing action are stretched, combed, and straightened between the stripping roller and the working roller. At this time, the linear velocity of the stripping roller needle surface is greater than the linear velocity of the working roller needle surface; similarly, the fibers are stretched and supplemented between the stripping roller and the cylinder. The fibers on the stripping roller are stretched and transferred to the cylinder. The cylinder continues to rotate with the fibers to the working area of the working roller. The fibers are combed again, and the linear velocity of the cylinder needle surface is greater than the linear velocity of the stripping roller needle surface.

According to the above combing and stripping process, the fibers are repeatedly combed, and finally the fibers form a uniformly mixed single fiber state, and are transferred to the web laying working area through the doffer to form thin fibers.

The condensation output system includes a doffer, a first condensation roller, and a second condensation roller, and a winding conveyor belt is arranged on the output side. In order to improve the orientation of the fibers, the condensation output system does not use a messy roller.

When the combed fibers approach the doffer, one end is captured by the doffer’s needle teeth, so that the fibers are transferred from the high-speed rotating cylinder to the doffer. Set the speed of the doffer to 𝑉𝑎, the speed of the first condensing roller to 𝑉𝑏, the speed of the second condensing roller to 𝑉𝑐, and the speed of the winding conveyor belt to 𝑉𝑑. According to the empirical process parameters, 𝑉𝑎/𝑉𝑏 is set to 2-3, 𝑉𝑏/𝑉𝑐 is set to 1.5-4, and 𝑉𝑐/𝑉𝑑 is set to 0.1-0.16. The fully combed fibers are condensed and transferred in this system to form a fiber web.

1.1.2 Cross-Lapping

After the carding is completed, the obtained RCF/PP thin fiber web is cross-lapped to obtain a fluffy thick fiber web. The carded thin fiber web is output to the web laying device through the doffer. The thin fiber web is gently laid on the clamping curtain at a constant rate. The clamping curtain is driven by the pulley to make the thin fiber web do a horizontal reciprocating motion on the web curtain, and it can be folded into a fluffy fiber web with a certain thickness. Finally, the web curtain outputs the web-laying completed fiber web to the consolidation device at a constant speed.

The movement speed of the pulley and the web curtain will affect the web laying angle. Therefore, the movement speed of the two is set to make the web laying angle extremely small. Finally, the output direction of the fiber web on the web curtain is almost perpendicular to the carding web output direction of the fiber web.

Since the directions of carding and cross-laying play a decisive role in the orientation of RCF in the formed nonwoven fabric, in order to facilitate subsequent analysis, the formed nonwoven fabric is divided into directions based on this, that is, the output direction of the carded web (carding direction) is recorded as CD (Carding Direction), and the direction perpendicular to it is recorded as PD (Perpendicular Direction), as shown in Figure 6.

1.1.3 Consolidation Method

The fluffy thick fiber web formed by cross-laying is transported by the web curtain and enters the consolidation device. There are two consolidation methods in this article: needle punching consolidation and thermal bonding consolidation.

(1) Needle Punching Consolidation

The needle punching mechanism is the key mechanism in the needle punching equipment. The most important devices include needle beam, needle board, needle, stripping plate and net support plate. The needle board is installed on the needle beam and reciprocates under the drive of the eccentric wheel.

The needle density of the needle on the needle board is 15 pin/cm2, and the needle arrangement is evenly distributed so that the needle points on the surface of the fiber felt are evenly distributed.

As the names suggest, the net support plate and the net stripping plate are used to support the fiber web when the needle pierces the fiber web, and the latter is used to block the fiber web when the needle leaves the fiber web. The needle depth can be adjusted by changing the distance between the needle board and the net board.

Within a certain range, the increase in the needling depth can make the entanglement between the fibers more complete, improve the strength of the product, increase the number of fibers in the thickness direction, and help improve the interlayer performance of the composite material. However, excessive needling depth will damage more RCF, which will have a negative impact on the performance of the composite material.

Therefore, choosing the right needling depth is also one of the key points in preparing high-performance RCF/PP composite materials.

In this experiment, the needling depth is 10 mm.

As shown in Figure 7 (a), the principle of needling consolidation is that the needle repeatedly punctures the fiber web, and the needle hooks the fiber, so that some horizontal fibers are entangled with each other in the fiber web into vertical fiber clusters. The vertical fiber clusters are entangled with the horizontal fibers, which effectively prevents the horizontal fibers from slipping off each other and makes the fiber web structure tight, thereby achieving the purpose of reinforcement. Since the needle and the fiber need to be in constant contact and friction, this mechanical processing method will cause certain damage to the fiber.

The finished needle felt is shown in Figure 7 (b). In order to facilitate the discussion of the performance of RCF/PP fiber felt under different consolidation processes, the needle-punched consolidated fiber felt is recorded as NP (Needle-punched).

(2) Thermal Bonding Consolidation

As shown in Figure 8 (a), thermal bonding consolidation is carried out in a double-belt press, with the heating roller and cooling roller pressure set to 130-180 N/cm2 and the heating roller temperature set to 160-180°C. The process of the thick fiber web passing through the double-belt press is specifically to sandwich the thick fiber web between the fluororesin-coated glass fiber cloth belts and wind it on the heating rollers, heating it while running, and pressurizing it between the heating rollers at a set pressure. Part of the PP fiber is heated and melted in this process; then, it passes through the cooling roller under the same cloth belt and pressure, and the fiber web is cooled and solidified at the outlet, and part of the PP in the fiber web is bonded, which plays a role in consolidation.

The finished product of the thermal bonding felt is shown in Figure 8 (b). Thermal bonding consolidation reduces the friction between the fiber and the metal instrument, and also reduces the friction between the fibers.

Similarly, the thermally bonded fiber felt is recorded as TB (Thermo-bonded) molding, and the instrument used is the XLB flat vulcanizer (Shanghai Qicai Hydraulic Machinery Co., Ltd.), which has both hot pressing layer and cold pressing layer. The hot pressing and cold pressing processes are completed automatically, and the hot pressing pressure, hot pressing time and hot pressing temperature need to be set before starting. In the previous exploration of the research group, based on experimental experience, the influence of hot pressing pressure, hot pressing time and hot pressing temperature on the morphology and thickness of the final composite material has been preliminarily clarified.

Among them, the hot pressing temperature and hot pressing time have a greater influence on the morphology of the final composite material. The effects of inappropriate hot pressing temperature and hot pressing time on the composite material include: overall shrinkage, resin overflow, and the thickness of the composite material does not meet the requirements.

In addition, the pressure holding and cooling (cold pressing stage) after the hot pressing is completed has a significant effect on the thickness of the composite material. Therefore, in this study, in order to explore the optimal hot pressing molding process parameters of the two non-woven fabrics in the study, the hot pressing molding parameters of the composite material, the sample type and its number are set as shown in Table 1 and Table 2.

2 Experimental Methods

2.1 Characterization and Performance Test of RCF/PP felt

2.1.1 Thickness of RCF/PP Felt

According to the requirements of GB/T 24218.2-2009 standard, first cut a sample with an area of 2500 mm2; configure a weight of 125 cN on the thickness gauge to make the pre-pressure reach 0.5 kPa, and set the pressure time to 10 s and the number of tests to repeat 10 times. Record the data obtained from the thickness test of needle-punched felt and thermally bonded felt, and calculate the average value of the thickness.

2.1.2 Gram Weight of RCF/PP Felt

After obtaining the thickness of carbon felt, the gram weight of needle-punched felt and thermally bonded felt was measured according to GB/T 24218.1-2009. Cut RCF/PP carbon felt with an area of 50000 mm2, weigh the corresponding carbon felt using an electronic scale, and calculate the gram weight of carbon felt. Each sample was measured 10 times to obtain the average weight of carbon felt.

2.1.3 Air Permeability Test Of RCF/PP Felt

The air permeability of needle-punched felt and thermally bonded felt was tested and evaluated using YG461E fabric automatic air permeability instrument according to GB/T5453-1997.

Before starting the test, the pressure drop was set to 200Pa; during the test, the carbon felt was placed on the sample round table, and 10 parts in the middle of each sample were randomly selected for air permeability testing.

Finally, the test results were calculated to obtain the average air permeability and coefficient of variation (CV value).

The coefficient of variation can indicate the degree of discreteness of the value, that is, it can reflect whether the air permeability of each part of the carbon felt is stable, and it can also indirectly reflect whether the fiber distribution and felt structure in each part of the carbon felt are uniform.

The Air Permeability �� (mm/s) Can Be Obtained By Formula (1):

2.2 Characterization and Performance Test of RCF/PP Composite Materials

2.2.1 Thickness of RCF/PP Composite Materials

The thickness of the molded RCF/PP composite materials was measured by using a spiral micrometer. During the measurement, the data of the upper, middle and lower positions were randomly selected on each sample to record and calculate the average thickness.

2.2.2 Fiber Length of RCF in RCF/PP Composite Materials

The RCF/PP composite materials were cut into 100mm×100mm sizes by a cutting machine, wrapped in tin foil, and placed in a muffle furnace. In order to fully burn the polypropylene and reduce the oxidation of carbon fibers, the temperature of the muffle furnace was set to 380℃ and the burning time was 2 hours. After burning, the polypropylene was thermally decomposed, leaving only carbon fibers.

Samples were taken in the middle of the burned samples because the carbon fibers at the edges were cut off due to cutting the samples.

When measuring the length of a single filament, it is necessary to pick out a single carbon fiber with tweezers, arrange it on white paper, and measure it manually with a vernier caliper. During the sampling process, it is necessary to prevent the carbon fiber from being pinched off by the tweezers, causing secondary damage and affecting the accuracy of the results.

Finally, polypropylene is thermally decomposed, leaving only carbon fiber. Samples are taken in the middle of the burned sample because the carbon fiber at the edge is cut off due to cutting the sample.

When measuring the length of a single filament, it is necessary to pick out a single carbon fiber with tweezers, arrange it on white paper, and measure it manually with a vernier caliper. During the sampling process, it is necessary to prevent the carbon fiber from being pinched off by the tweezers, causing secondary damage and affecting the accuracy of the results.

2.2.3 Mechanical Properties of RCF/PP Composite Materials

According to the standard JIS K7113-1995, a universal testing machine is used to test the tensile properties of composite materials. Three samples of each sample are tested and the results are averaged.

3 Results and Discussion

3.1 Properties of RCF/PP Felt

3.1.1 Thickness and Gram Weight of RCF/PP Felt

Because the nonwoven process uses two different consolidation processes, the needle-punched felt obtained by needle-punching consolidation is recorded as NP, and the thermally bonded felt obtained by thermal bonding consolidation is recorded as TB. The results of measuring the thickness and gram weight of the two are shown in Table 3.

In terms of thickness, the thickness of the RCF/PP fiber felt obtained by the needle punching process is much greater than that of the thermally bonded fiber felt. The needle punched felt appears to be more fluffy, while the thermally bonded felt is more compact. The difference in thickness also makes the thermally bonded felt occupy a smaller volume in industrial production and transportation, which is more conducive to storage and transportation.

In terms of unit area mass, the gram weight of the RCF/PP fiber felt obtained by the needle punching process is 228.2 g·m-2, and the gram weight of the thermally bonded felt is 258.1 g·m-2. The change in the consolidation method has little effect on the gram weight of the nonwoven fabric.

In addition, the coefficient of variation of the thickness and gram weight of the fiber felt is relatively small, and the thickness and gram weight at different positions are relatively uniform, indicating that the sample morphology is relatively regular.

3.1.2 Air Permeability of RCF/PP Felt

The air permeability of needle-punched and thermally bonded RCF/PP fiber felts is shown in Table 4. The air permeability of needle-punched felt is 835.13% ± 1.78%, while that of thermally bonded felt is 652.13% ± 9.13%.

As can be seen from the table, on the one hand, the air permeability of thermally bonded felt is lower than that of needle-punched felt. This is because the polypropylene in the thermally bonded felt is partially melted and solidified, forming multiple bonding points, and the structure of the felt is relatively tight after pressing, while the needle-punched felt is solidified due to the entanglement of fibers and has a relatively loose structure; on the other hand, the coefficient of variation of the air permeability of needle-punched felt and thermally bonded felt is small, which indicates that the air permeability deviation of each part in the same felt is small, and the fiber distribution and felt structure in the fiber felt are relatively uniform.

3.2 Exploration of Hot Pressing Parameters of RCF/PP Composite Materials

In order to more objectively evaluate the performance of composite materials, the carbon fiber content per unit volume of composite materials is defined as ����, which can be calculated by formula (2):

Referring to the carbon fiber content per unit volume of composite materials in previous studies, it is calculated that the ideal thickness of the needle felt hot press composite material sample after 9 layers is 1.825 (± 0.026) mm, and the ideal thickness of the heat-bonded felt hot press composite material sample after 9 layers is 2.064 (± 0.027) mm, to ensure that the carbon fiber content per unit volume of the composite material is the same.

In hot press molding, its process parameters (pressure, temperature, time) have a decisive effect on the state of fiber and resin during molding and the thickness of the composite material after molding:

If the temperature is set too high or the time is too long, it will cause the resin and fiber to overflow; if the process parameter value is set too small, it will affect the complete melting of the resin and cause the thickness of the composite material to be too large, which will deteriorate the mechanical properties of the composite material.

When preparing RCF/PP composite materials, this paper conducted a series of experiments on hot press molding parameters to provide reference data for seeking hot press molding process parameters suitable for the above-mentioned fiber felt.

3.2.1 Preparation of Composite Materials from Needle Felt

25 cm × 15 cm specimens were cut from the needle felt along the PD and CD directions, with 9 specimens in each group. The hot pressing parameters and the thickness of the composite materials obtained by hot pressing are shown in Table 5.

The composite materials were numbered according to the test sequence. The composite materials with serial numbers 1 and 8 are shown in Figure 10, and the composite materials with serial numbers 2, 3, 4, 5, 6, 7, and 9 are shown in Figure 11.

As can be seen from Figure 9, the composite materials with serial numbers 1 and 8 shrink as a whole, causing many fibers to be exposed outside the edges. This is due to the uneven heating of the PP in the needle felt during the hot pressing process.

During the hot pressing process, the PP fluid that has reached the melting point penetrates into the carbon fiber layer and gathers together. However, it cannot spread due to insufficient pressure. The temperature of some PP in the middle layer has not yet reached the melting point, and the hot pressing time is up. The PP above and below are heated and become sticky, which brings the fibers in the middle layer closer to the middle. The applied pressure cannot disperse the gathered sticky fluid, resulting in thickening and shrinkage.

As shown in samples 2, 3, and 4 in Figure 10, the composite samples molded at 180 ℃, 185 ℃, and 190 ℃, with a pressure of 6 MPa and heating for 90 s also shrank, and the shrinkage became more serious as the temperature increased. This is because the temperature increased, making the PP melt faster and gather faster in the middle, but due to insufficient pressure or insufficient pressurization time, the PP fluid could not diffuse to the surroundings, resulting in severe shrinkage.

At the same time, after the temperature reached 185 ℃, the thickness of the composite sample decreased, slightly close to the ideal thickness. It can be concluded that a better composite sample can be obtained when the molding temperature is above 185 ℃.

As shown in sample No. 5 in Figure 10, when the hot pressing temperature is 190 ℃, the hot pressing time increases from 90 s to 120s, and the cooling time also increases from 90s to 120s, the resin fluid has sufficient time to diffuse and solidify around, avoiding the shrinkage of the composite sample, and the resin loss phenomenon is not obvious.

At the same time, when the cold pressing time increases, the thickness of the composite material sample decreases accordingly, which shows that the cold pressing time affects the molding thickness. The average thickness of the composite material sample formed by hot pressing is 1.712 mm, which is within the ideal thickness error range, so the molded sample is usable.

As shown in samples 6 and 7 in Figure 10, the composite material sample formed at 190℃ and pressure of 7MPa has increased hot pressing pressure and reduced shrinkage compared with sample 4 formed at 190℃ and pressure of 6MPa. Therefore, increasing the pressure to 7MPa can slightly improve the shrinkage.

As shown in sample 9 in Figure 10, when the hot pressing temperature reaches 195℃, the composite material sample shrinks less in the longitudinal direction, but becomes wider in the transverse direction. The temperature is too high, and resin overflow occurs.

In summary, when the hot pressing temperature, pressure and pressing time are not enough to make the PP fluid fully diffuse and solidify, the molded composite material sample shrinks; when the temperature is too high, the molded composite material will have obvious resin overflow; therefore, the appropriate hot pressing molding parameters for preparing NP composite material samples can be: hot pressing temperature of 190 ℃, hot pressing and cold pressing pressure of 6 MPa, hot pressing time of 120 s, and cold pressing time of 120 s.

3.2.2 Test of Preparing Composite Materials by Thermal Bonding Felt

25 cm×15 cm specimens were cut from thermal bonding felt along the PD and CD directions, with 9 specimens in each group. The temperature, pressure, heating time and cooling time were gradually increased, and the test sequence was also numbered. The hot pressing test parameters and the thickness of the obtained composite material samples are shown in Table 6.

The initial molding pressure was set to 5 MPa, the hot pressing time was 65 s, and the cold pressing time was 65 s. The thickness of composite material sample No. 10 was measured to be 2.623 mm, which was larger than the ideal thickness.

The cold pressing time of sample No. 11 increased from 65s to 120s, and the hot pressing time was increased to 70s. According to the conclusion obtained in 3.2.1, the increase of cold pressing time will reduce the thickness of the molded composite sample. The thickness of composite sample No. 2 is reduced compared with No. 1, but the difference is not large. This is because PP is not fully melted and flowed. Even if the cold pressing time is sufficient during cooling and solidification, the composite sample is still relatively thick.

As shown in Table 6 for samples No. 12-17, when the hot pressing temperature and pressure are gradually increased, PP is fully melted and diffused during the hot pressing process, and the thickness of the composite sample decreases accordingly.

As shown in Table 6 for samples No. 16 and No. 17, when the temperature reaches 177℃ and 180℃ and the pressure is 7 MPa, the thickness of the composite samples of the two are close to the ideal thickness, and the thickness of the final molded sample is within the thickness error range of the thermal bonding composite material, so the molded sample is usable.

As shown in Figure 11, the TB-PD hot press-molded composite sample No. 17 maintains a stable size without shrinking or widening using the corresponding hot press parameters.

In summary, during hot press molding, PP needs to be fully melted at the appropriate temperature and time, fully flow and diffuse at the appropriate pressure, and have enough time to solidify during cold pressing, so all parameters are complementary.

The appropriate hot press molding parameters for preparing TB composite samples can be: hot press temperature 177 ℃-180 ℃, hot and cold press pressure 7 MPa, hot press time 70 s, cold press time 120 s.

3.3 Performance of RCF/PP Composite Materials

3.3.1 Thickness of RCF/PP Composite Materials

There are four types of RCF/PP composite materials for tensile specimens. Three tensile tests were performed on each specimen. Table 7 shows the thickness of the four tensile specimens. The coefficient of variation of the same type of samples is small. Under appropriate molding parameters, the thickness of the obtained samples is uniform.

3.3.2 Fiber Length of RCF in RCF/PP Composites

The RCF/PP composites were cut into 100 mm × 100 mm pieces by a cutting machine. After being calcined at 380 °C for 2 hours, samples were taken from the middle of the calcined samples. The length distribution of RCF is shown in Figure 12 (a). The average length of RCF is 30.4 (±45.5%) mm.

Most of them are distributed between 10-50 mm. The original length of RCF was measured to be 44.6 (±28.63%) mm. Compared with the original length of RCF in Figure 12 (b), it can be clearly seen that the length of RCF in the composite is shorter than the original length of RCF before non-woven, which proves that the non-woven process has a certain damage to the length of RCF.

3.3.3 Mechanical Properties of RCF/PP Composites

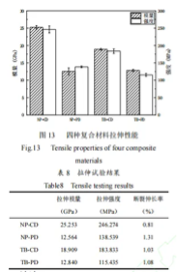

Through observation, there is no obvious change on the surface of the sample during the stretching process. There is a sound before breaking, a loud noise is produced at the moment of breaking, and then the load quickly returns to zero. Table 7 shows the tensile test results of the four composite materials. Figure 13 shows the tensile properties of the RCF/PP composite materials formed by hot pressing at room temperature under four processing conditions.

It can be clearly seen from the figure that, on the one hand, from the perspective of consolidation process, the tensile strength of the samples prepared by needle-punched fiber felt (NP-CD and NP-PD) is higher than that of the corresponding samples prepared by thermally bonded fiber felt (TB-CD and TB-PD). Therefore, from the existing data, the mechanical properties of the composite materials obtained by needle-punching reinforcement are better than those of thermal bonding process.

On the other hand, from the perspective of direction, the tensile strength of the needle-punched sample NPCD and the thermally bonded sample TB-CD are higher than those of NP-PD and TB-PD, respectively, indicating that under the same process, the tensile properties in the CD direction are better than those in the PD direction. The tensile properties in the CD direction of the needle-punched felt are 77.8% higher than those in the PD direction, and the tensile properties in the CD direction of the thermally bonded felt are 59.3% higher than those in the PD direction.

When preparing RCF/PP fiber mats through nonwoven fabrication, RCF undergoes a combing and web laying process, and most of the fibers are oriented along the combing direction, which determines that the final molded composite material has anisotropy.

4 Conclusion

This paper uses RCF and PP as raw materials to prepare RCF/PP fiber mats and their hot-pressed composite materials. The RCF/PP fiber mats and RCF/PP composite materials are taken as research objects to study their properties. The main research results of this paper are summarized as follows:

(1) Preparation of RCF/PP fiber mats: The preparation process is pre-opening and mixing, carding and web formation, cross-laying, and needle punching/thermal bonding reinforcement. A set of non-woven process parameters that can be used for RCF and PP fibers was found through experiments.

First, for the carding and web formation stage, set 𝑉𝑎/𝑉𝑏 to 2-3, 𝑉𝑏/𝑉𝑐 to 1.5-4, and 𝑉𝑐/𝑉𝑑 to 0.1-0.16. The fibers form an ordered and oriented single fiber morphology under the interaction between the cylinder and the roller.

Second, during the cross-laying process, the laying angle is extremely small, and the final output direction of the fiber web on the web curtain is almost perpendicular to the carding web output direction of the fiber web.

Third, the needle punching density of 15 pin/cm2 and the needle punching depth of 10 m are used for needle punching consolidation; the pressure of 130-180 N/cm2 and the temperature of 160-180 ℃ are used for thermal bonding consolidation.

(2) Preparation of RCF/PP fiber felt hot press composite materials: The preparation process is sample preparation, hot pressing, and cold pressing. The optimized molding parameters of needle felt and hot bonding felt were determined by experiments.

The hot pressing temperature of needle felt is 190 ℃, the pressure is 6 MPa, and the hot pressing and cold pressing time are both 120 s; the hot pressing temperature of hot bonding felt is 177-180 ℃, the pressure is 7 MPa, the hot pressing time is 70 s, and the cold pressing time is 120 s.

(3) Study on the properties of RCF/PP fiber felt and RCF/PP composite materials: The thickness and gram weight of the fiber felt at different positions are relatively uniform, the air permeability deviation is small, and the fibers in the felt are evenly distributed; the tensile properties of the composite material obtained by needle-punched felt are better than those obtained by thermally bonded felt; the tensile properties in the CD direction are better than those in the PD direction, and the RCF/PP composite material is anisotropic.

ANY QUESTIONS OR COMMENTS, PLEASE GET A HOLD OF US IN WHICHEVER WAY IS MOST CONVENIENT. WE WILL REPLY YOU WITHIN 24 HOURS.